Dynamic compressors are an integral part of various industrial processes, offering efficient solutions for applications requiring continuous-flow compression. These compressors are broadly categorized into two types: centrifugal and axial flow compressors. Both play critical roles in industries such as petroleum refining, chemical processing, and natural gas transportation.

Centrifugal Compressors

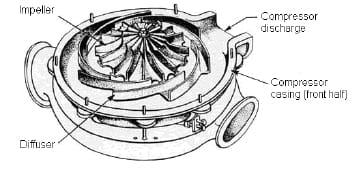

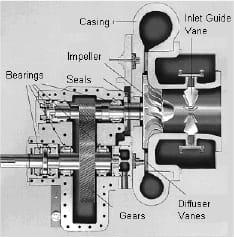

Centrifugal compressors operate on the principle of imparting energy to gas through rapidly rotating impellers, which increase the velocity and subsequently convert it into pressure energy. These compressors are widely used due to their compact design and reduced vibration compared to positive displacement compressors.

Key Features:

- Compression Mechanism: Gas enters axially and is discharged radially, gaining velocity and pressure.

- Components: Includes impellers and diffusers (vaneless or vaned).

- Performance: Ideal for single-stage designs with intake volumes ranging from 100 to 150,000 acfm and multistage designs for pressures up to 2352 psi.

Configurations:

- Horizontally-split Casings: Suitable for pressures below 60 bars.

- Vertically-split Casings: Designed for high-pressure applications (up to 700 kg/cm²).

- Bell Casings: Barrel compressors for high-pressure scenarios.

- Pipeline Compressors: Optimized for natural gas transportation.

- SR Compressors: Feature overhung impellers for lower-pressure services.

Advantages and Disadvantages:

Advantages

High efficiency comparable to reciprocating compressors

Compact and lubricant-free operation

Does not need special foundations

Disadvantages

Requires sophisticated monitoring systems

Limited capacity control modulation

High-speed operation demands specialized maintenance

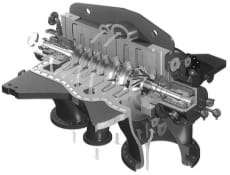

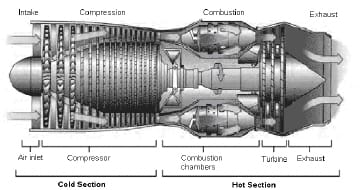

Axial Flow Compressors

Axial flow compressors are primarily utilized in gas turbines, large nitric acid plants, and steel industry operations. These compressors excel in handling high intake volumes with lower pressure heads and offer higher efficiency than centrifugal compressors.

Key Features:

- Compression Mechanism: Gas flows parallel to the axis, accelerated by rotating blades (rotor) and diffused by stationary blades (stator).

- Components: Rotating drum with decreasing blade heights and precise blade angles.

- Performance: Capable of intake volumes between 23,500 to 588,500 acfm with pressures exceeding 100 psi.

Advantages and Disadvantages:

Advantages

High efficiency and low pressure loss

Compact design for high-volume applications

Disadvantages

Limited pressure increase per stage

Requires multiple stages for significant pressure rise

Dynamic compressors, including centrifugal and axial flow types, provide versatile and efficient solutions for modern industrial demands. Understanding their characteristics and configurations helps in selecting the right compressor for specific applications.

Why Choose TRYCOMP?

TRYCOMP specializes in providing cutting-edge compressor solutions tailored to various industrial needs. With a commitment to innovation and quality, TRYCOMP offers a range of dynamic compressors, ensuring optimal performance and reliability. Explore more about TRYCOMP’s offerings by visiting our website.